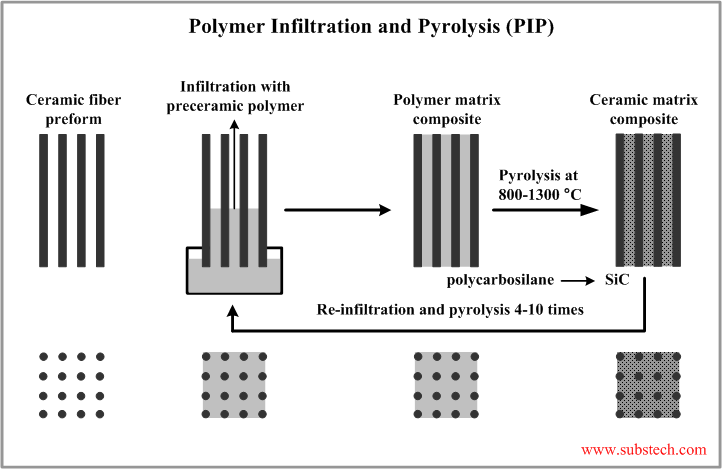

In this process a fiber architecture which can be either a simple fiber tow or a multidirectional fiber preform is chemically coated with a ceramic interphase such as c b or bn and then densified with a ceramic matrix such as sic or a multilayered sic based matrix containing boron bearing species in a hot wall deposition chamber from appropriate gaseous precursors.

Matrix ceramic bearings.

Under compressive stress the ceramic static bearing has a low risk of failure but a sic shaft sleeve does not have this situation and must therefore have a large wall thickness and or be specially designed.

This includes ceramic bearings cutting tools extrusion dies valves sealing rings and cylinder liners etc.

Especially ceramics could be the best suitable material in those tribological applications with high load and precision requirement or corrosive environment such as turbopump in space engine total knee joint replacement and hip.

Influence friction and wear tribology influence thermal expansion.

The objectives of the technical and application specific structure design for such ceramics include.

Cmcs perform particularly well in abrasive conditions including but not limited to those found in glycol applications.

Ceramic matrix composites are used in higher duty conditions in terms of contact pressure surface speeds and fluid lubricity.